MANUFACTURING PROCESS

CAPABILITY

Solutions designed to meet your needs,

delivered with precision die-casting technology

1. Design review

In order to realize the cutomer requested design, we will offer our proposal that best fit the knowledge we have accumulated.

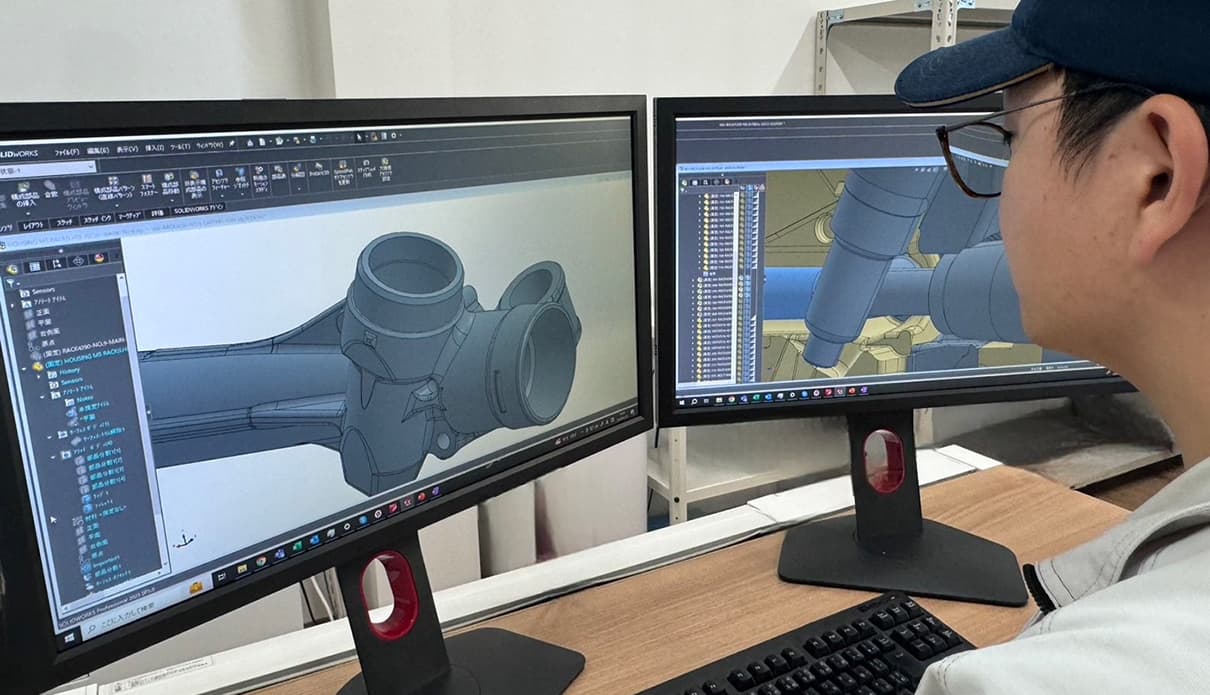

2. Mold design

We use 3D printing to replicate product shapes and employ CAE (flow analysis software) to design optimal casting plans. This approach ensures precision in casting and enhances production efficiency.

3. Cutting tool design

By leveraging advanced simulations in our custom tool and jig design processes, we identify and address potential issues—such as machining conditions and clamp deformation—before production. This proactive approach allows us to meet our customers' stringent precision requirements, starting from scratch to ensure high-quality results.

4.

Mold

Manufacturing

We produce high-precision molds using designs enhanced by advanced analysis technology, and we manufacture them with state-of-the-art mold production equipment. This approach ensures the highest level of quality and precision in every mold we create.

CAPABILITIES - SHIN-EI HIGH TECH CO., LTD.

-

LATHE MACHINE (MAZAK)

1 Unit -

NC LATHE MACHINE

4 Units -

NC MILLING MACHINE

7 Units -

HORIZONTAL BORING MILLING MACHINE (MITSUBISHI)

1 Unit -

MACHINING CENTER

14 Units -

DOUBLE COLUMN TYPE MACHINE (MITSUBISHI)

1 Unit -

GRINDING MACHINE

3 Units -

NC WIRE CUT MACHINE

5 Units -

ELECTRICAL DISCHARGE MACHINE

8 Units -

LASER BEAM WELDING

1 Unit -

MOLD FLOW ANALYZER

1 Unit -

DIE SPOT

2 Units -

CMM

1 Unit -

CAD / CAM

15 Units

5.

Cutting Tools

Manufacturing

We utilize cutting-edge wire-cut EDM hybrid machines to create unique, high-quality tools that are not found elsewhere. A key strength of our process is achieving just-in-time delivery through rapid turnaround, completing designs to production within just a few days.

SHIN-EI HIGH TECH CO., LTD. - TOOL DIVISION

-

UNIVERSAL TOOL GRINDING

3 Units -

MACHINING CENTER

4 Units -

MILLING MACHINE

1 Unit -

LATHE MACHINE

3 Units -

TOOL MICROSCOPE

3 Units -

TOOL DYNAMIC BALANCE MACHINE

1 Unit -

3D CAD (SOLID WORKS)

18 Units -

CAM MC (SOLID WORKS)

1 Unit -

CAM NC (SOLID WORKS)

1 Unit -

SIMULATION SYSTEM (SOLID WORKS)

1 Unit -

CNC GRINDING MACHINE - CARBIDE

1 Unit

(WALTER) -

CNC GRINDING MACHINE - DIAMOND

1 Unit

(WALTER) -

CNC WIRECUT MACHINE (FANUC)

1 Unit -

CNC WIRECUT MACHINE (VOLLMER)

3 Units -

CYLINDRICAL GRINDER MACHINE

4 Units -

3D PRINTER (250 x 250 x 250)

2 Units

(STARTASYS) -

3D MEASURING INSTRUMENT

1 Unit

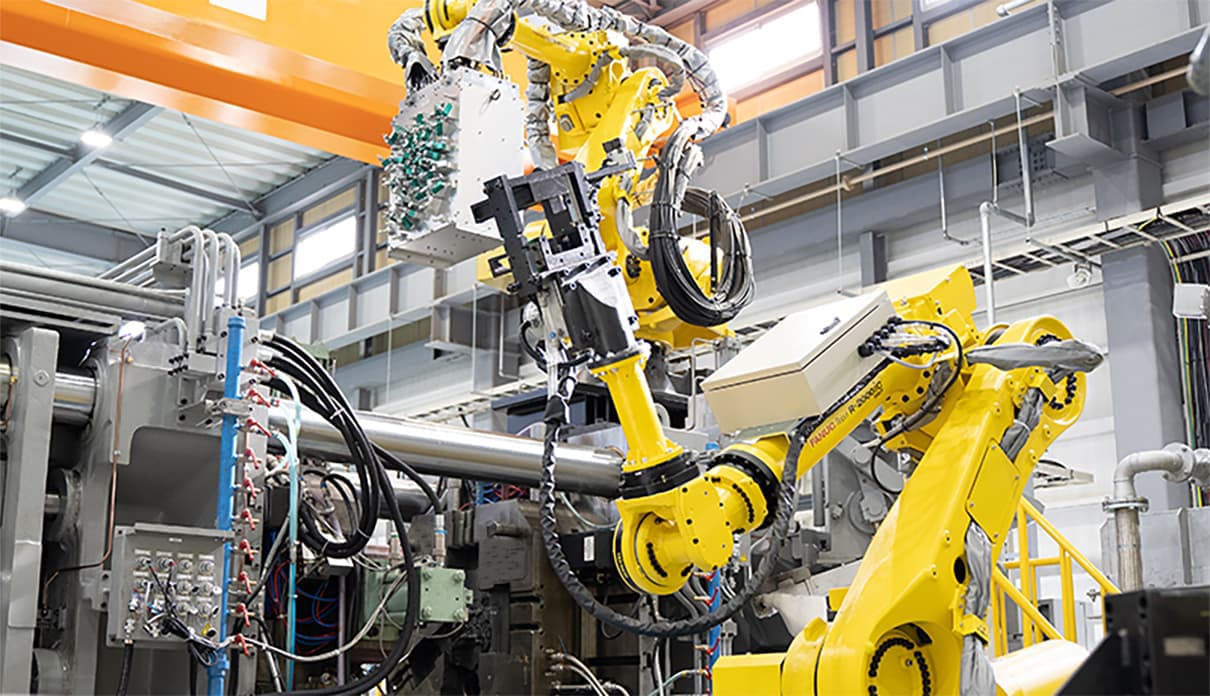

6.

High Pressure

Diecast

We are committed to maximizing productivity in casting through designs driven by advanced analysis technologies, ensuring efficiency and precision in every step of the process.

SHIN-EI HIGH TECH CO., LTD.

Suranaree Industrial Zone

-

350 t

16 Units -

Sub total

16 Units -

ROBOT FOR AUTOMATION

13 Units

SHIN-EI HIGH TECH CO., LTD.

Navanakorn Industrial Zone

-

350 t

17 Units -

650 t

1 Unit -

670 t

1 Unit -

800 t

1 Unit -

850 t

17 Units -

1,100 t

9 Units -

1,250 t

2 Units -

1,650 t

1 Unit -

Sub total

49 Units -

ROBOT FOR AUTOMATION

138 Units

SHIN-EI PRECISION (THAILAND) CO., LTD.

Rojana Industrial Zone - Ayutthaya

-

350 t

14 Units -

Sub total

14 Units -

ROBOT FOR AUTOMATION

25 Units -

DC GRAND TOTAL

79 Units -

ROBOT FOR AUTOMATION GRAND TOTAL

176 Units

7.

Gravity

Diecast

Gravity die casting is a production method in which molten aluminum takes shape under its own weight. This process offers high design flexibility, enabling the creation of complex hollow structures that are difficult to achieve with high-pressure die casting. Additionally, since the mold fills by gravity, it minimizes air entrapment, thereby reducing the risk of porosity in the final product.

SHIIN-EI HIGH TECH CO., LTD.

Suranaree Industrial Zone

-

Gravity Casting Machine

20 Units -

Shell Mounding Machine

19 Units -

De-Gassing Apparatus

3 Units -

Coagulation Tester

1 Unit -

T6 Treatment Furnace

4 Units -

T5 Treatment Furnace

1 Unit -

Fanuc Robot

27 Units

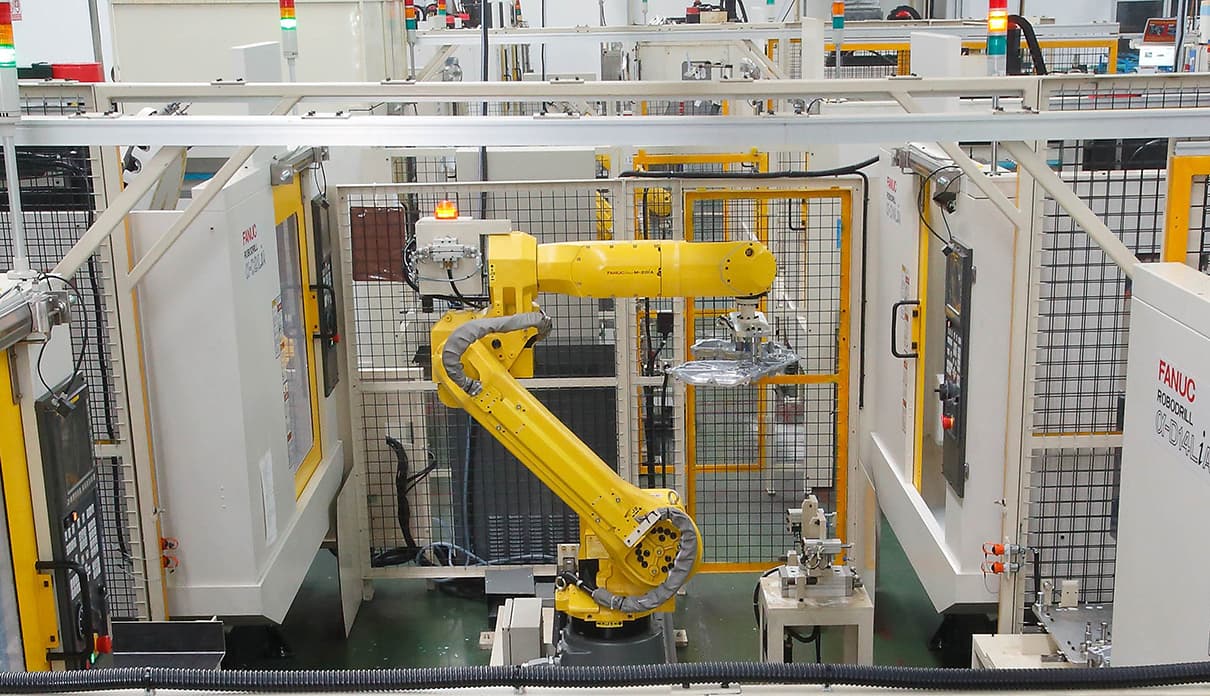

8. Machining

With over 1,000 CNC machines, we leverage cutting-edge manufacturing equipment and in-house developed automation systems to enhance our mass production capabilities. Our focus is on achieving unparalleled precision through advanced technology and production expertise.

SHIN-EI HIGH TECH CO., LTD.

Suranaree Industrial Zone

-

NC LATHE MACHINE

113 Units -

MACHINING CENTER

141 Units -

Sub total

254 Units -

ROBOT FOR AUTOMATION

6 Units

SHIN-EI HIGH TECH CO., LTD.

Navanakorn Industrial Zone

-

NC LATHE MACHINE

66 Units -

MACHINING CENTER

514 Units -

Sub total

580 Units -

ROBOT FOR AUTOMATION

30 Units

SHIN-EI PRECISION (THAILAND) CO., LTD.

Rojana Industrial Zone - Ayutthaya

-

NC LATHE MACHINE

152 Units -

MACHINING CENTER

43 Units -

Sub total

195 Units -

ROBOT FOR AUTOMATION

53 Units -

MACHINE GRAND TOTAL

1029 Units -

ROBOT FOR AUTOMATION GRAND TOTAL

89 Units

9. Assembly

SHIN-EI has many different types of assembly processes ranging from Assy Pin & Oil Gauge, Ball insert, Shrinkage fitting. We can comply with customer requirements for assembled products.

10.

Quality

Assurance

We guarantee exceptional quality by using state-of-the-art CT scanners to inspect the internal structure of castings, along with high-precision 3D scanners and coordinate measuring machines for accurate dimensional measurements.

ANALYSIS MACHINE

-

HARDNESS TESTING MACHINE

5 Units -

AMSLER UNIVERSAL TESTING INSTRUMENT

2 Units -

PROFILE PROJECTOR

1 Unit -

X-RAY

1 Unit -

CT SCANNER (TOSHIBA & YXLON & NIKON)

4 Units -

3D SCANNER

3 Units -

SPECTROMETER

3 Units -

TMA

1 Unit -

QUICK VISION MACHINE (QV)

1 Unit -

MICROSCOPE FOR PHASE ANALIZER

2 Units -

BURST TEST MACHINE

1 Unit -

UNIVERSAL LENGTH MEASURING MACHINE (ULM)

1 Unit

MEASUREMENT MACHINE

-

CMM MACHINE (MITSUTOYO)

27 Units -

CMM MACHINE (CARL ZEISS)

3 Units -

HANDY CMM

3 Units -

CONTRACER & ROUGHNESS

4 Units -

ROUNDNESS TESTER

6 Units -

SURFACE TESTER

9 Units -

MICROSCOPE

4 Units -

CONTOUR

4 Units -

AIR MICROMETER

151 Units -

BURST TEST MACHINE

1 Unit

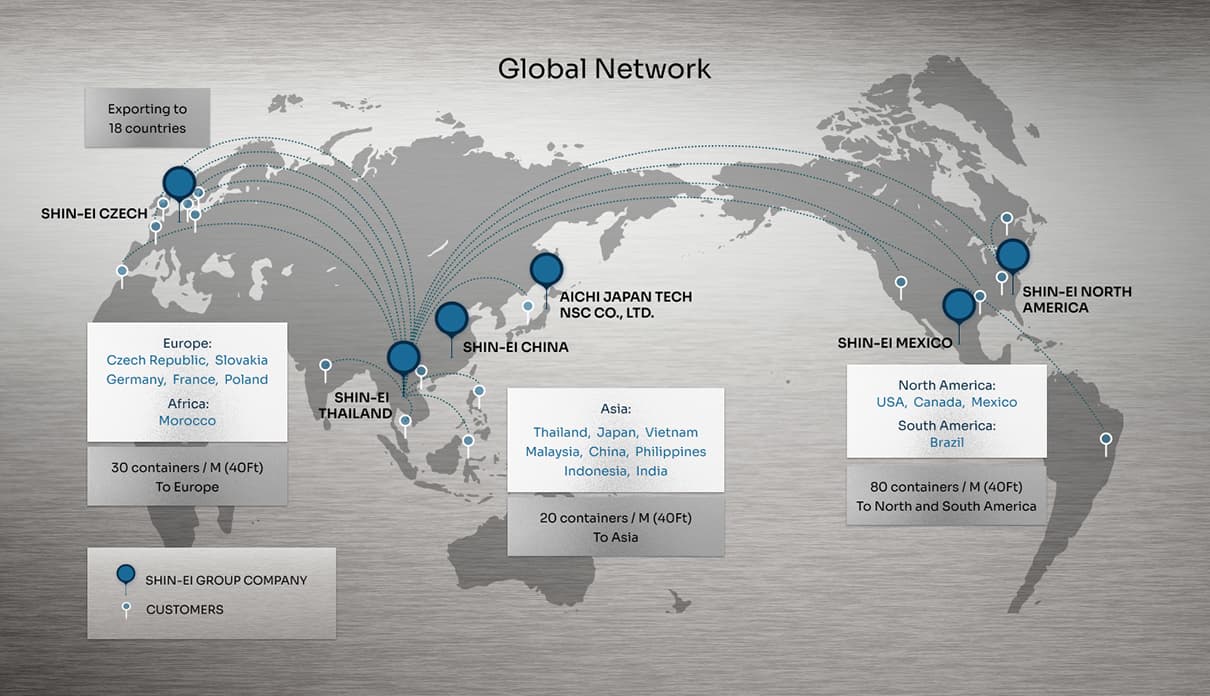

11. Delivery

We deliver high-quality, competitive products through our in-house logistics network to 16 countries across North America, Europe, and Asia.