PROCESS

Success from prototype to concept to Mass production

ORDER

ORDER

R&D / DESIGN

R&D / DESIGN

SHIN-EI has versatile capabilities to develop the production process of mold and jig fixture by using our original design and in-house process,

optimizing the design engineering with the shortest lead time.

Furthermore SHIN-EI have various highly precise machines, manufactured in Germany and Japan, that are enable us to produce original tooling and in-house jigs in Thailand. Therefore, we have realized as well as accumulated the knowhow and speedy setup of technical skills.

Furthermore SHIN-EI have various highly precise machines, manufactured in Germany and Japan, that are enable us to produce original tooling and in-house jigs in Thailand. Therefore, we have realized as well as accumulated the knowhow and speedy setup of technical skills.

PRODUCTION

PRODUCTION

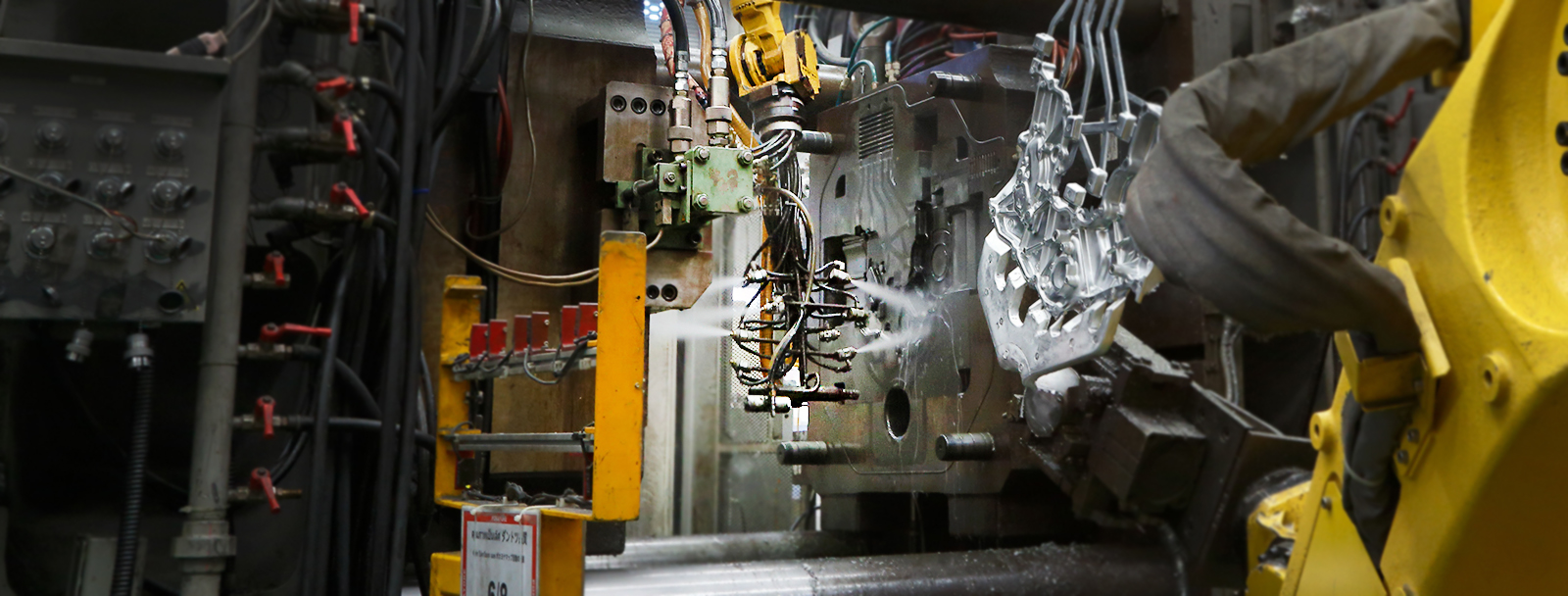

HPDC & GDC

HPDC: SHIN-EI has a large number of Die Casting machines with wide range of capabilities from 350ton to 1650ton, and they are also capable to produce luxury parts that can meet Global Automotive Standards.GDC: SHIN-EI has a thorough process of GDC starting from Shell Core making, GDC and T6 Heat Treatment.

SAND CASTING: SHIN-EI can produce sand casting prototype which helps for speedy product development, then can switch to HPDC or GDC for mass production .

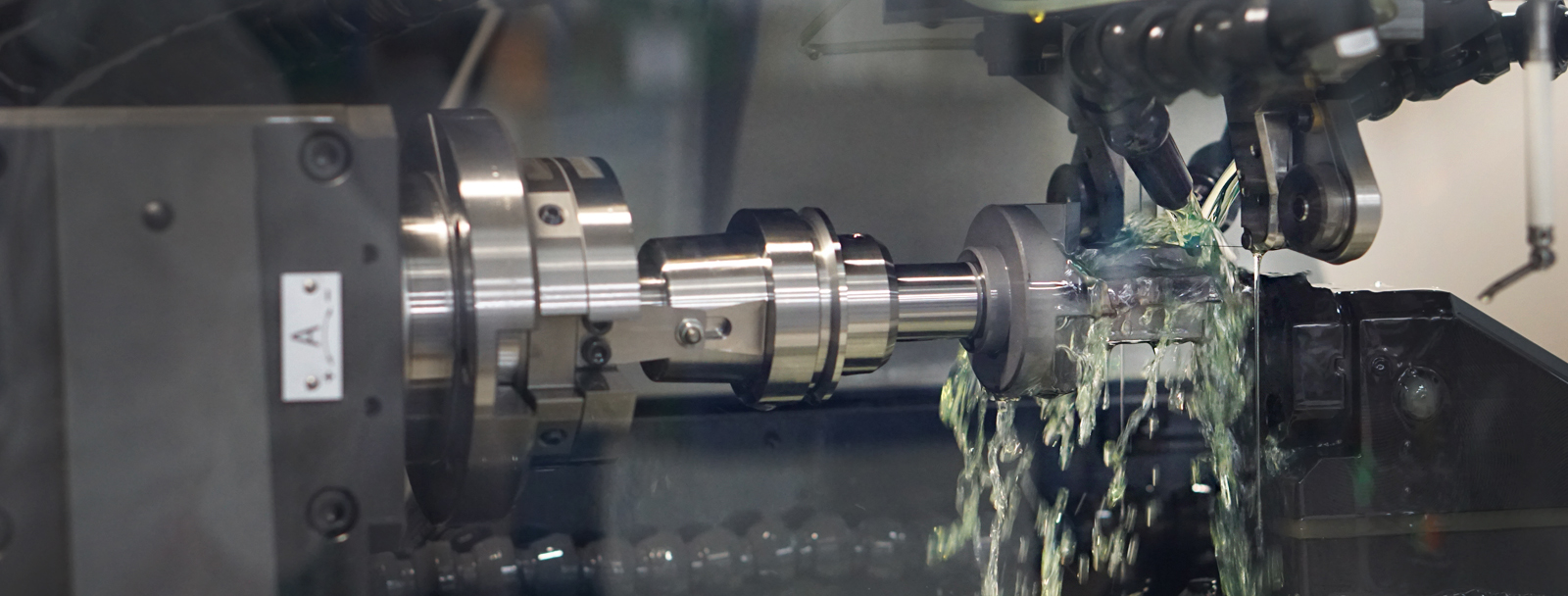

Machining

SHIN-EI has over 818 MC unit with a large variety of machinng capabilities that can control complex shapes and very tight tolelance up to 1 digit micrometers.

LEAKAGE DETECTION MACHINE

LEAKAGE DETECTION MACHINE

SHIN-EI has several kinds of fine leak detection process :

1. LEAK: Helium, Nitrogen, and Normal Air up to 15 Bar.

2. Hydraulic Decay: up to 20 Bar.

3. Water Decay:

1. LEAK: Helium, Nitrogen, and Normal Air up to 15 Bar.

2. Hydraulic Decay: up to 20 Bar.

3. Water Decay:

ASSEMBLY

ASSEMBLY

SHIN-EI has many different types of assembly processes ranging from Assy Pin & Oil Gauge, Ball insert, Shrinkage fitting.

We can comply with customer requirements for assembled products.

We can comply with customer requirements for assembled products.

QUALITY CHECK

QUALITY CHECK

SHIN-EI has a wide range of in house Quality Machinery: 3D Computed Tomography, X-Ray, CT Scan, 3D Scanner, CMM, Metrology Lab for metallurgical analysis of alloys,

and Unique Measurement methods to have a stabilized production, also SHIN-EI has automated data center that can collect both of digital data and real-time information.

DELIVERY

DELIVERY

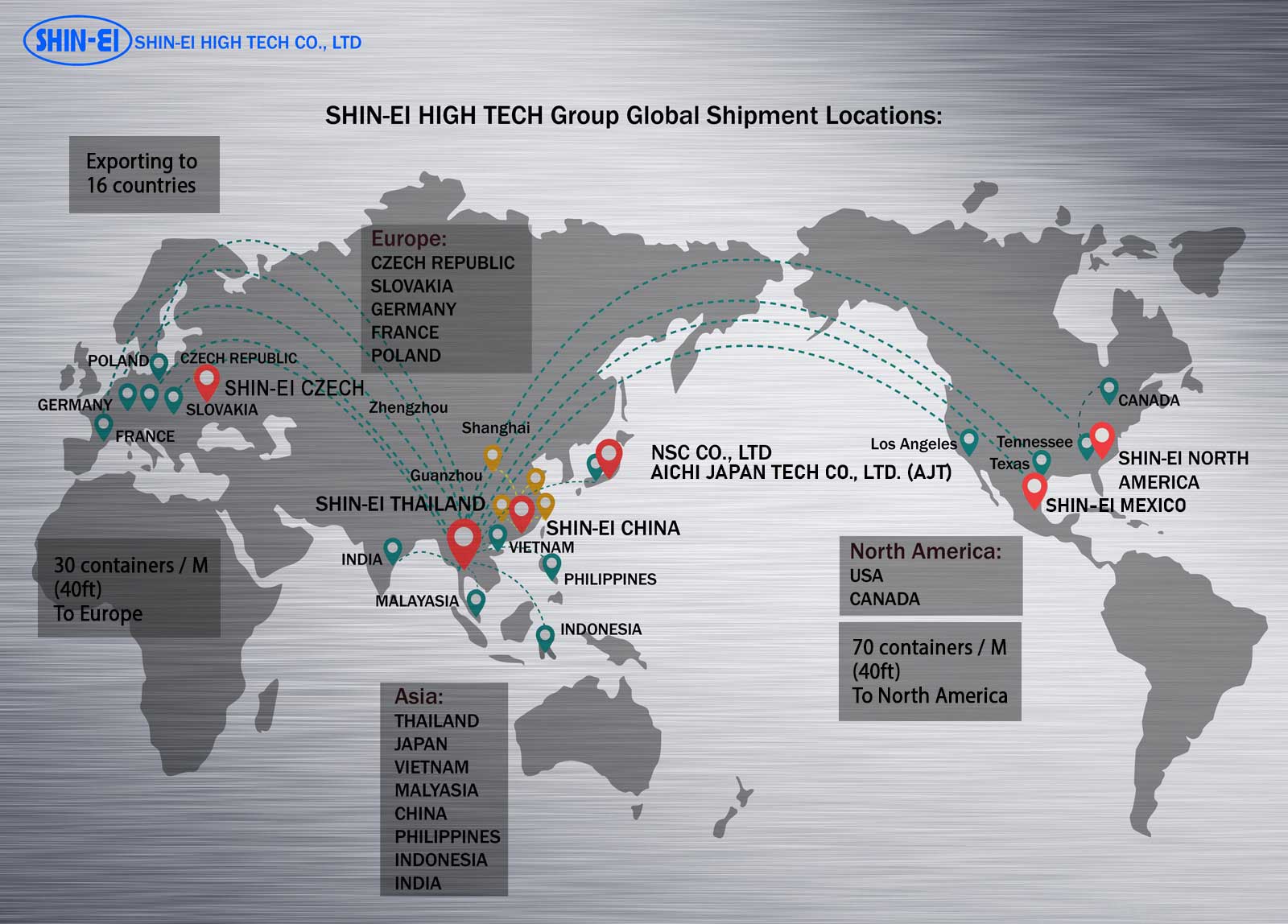

SHIN-EI can provide many incoterms that is can meet customer's requirements, resulting in the delivery across many countries.

SHIN-EI has achieved many awards including QCD for on-time delivery both of domestic and international level.